AUTOMATED ULTRASONIC TESTING (AUT)

Introduction

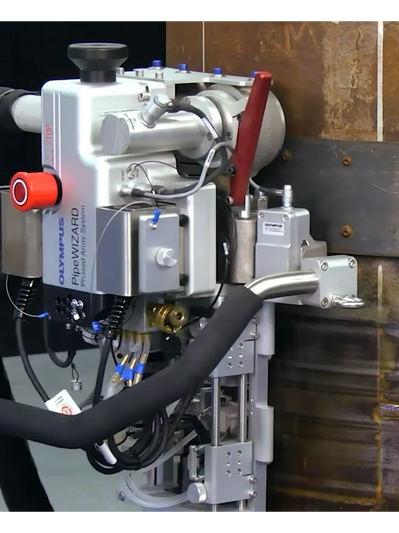

AUT of corrosion mapping & girth welds utilizes automated scanning systems equipped with ultrasonic probes to inspect the welds. The probes emit ultrasonic waves into the weld, and the reflected signals are analyzed to detect and characterize any flaws or defects. Phased array or conventional ultrasonic techniques can be employed, depending on the specific requirements and capabilities of the AUT system.

Application:

AUT of girth welds is primarily used in the oil and gas industry for pipeline construction and maintenance. It is employed to assess the quality and integrity of welds in new pipeline installations, as well as to monitor and inspect existing pipelines for integrity assurance and safety purposes. AUT is crucial for identifying flaws such as lack of fusion, lack of penetration, cracks, and other discontinuities that can compromise the weld strength and structural integrity.

Standard Code Reference:

The industry relies on various codes and standards to guide AUT of girth welds, including

- API 1104 (American Petroleum Institute) - "Welding of Pipelines and Related Facilities,"

- ASME B31.8 (American Society of Mechanical Engineers) - "Gas Transmission and Distribution Piping Systems," and

- ISO 17636 - "Non-destructive testing of welds - Ultrasonic testing of welded joints."

Advantages:

- High Inspection Speed: AUT systems can rapidly scan long lengths of girth welds, significantly reducing inspection time compared to manual methods.

- Accurate and Reliable: AUT provides accurate and repeatable inspection results, reducing the risk of human error and ensuring consistent assessment of weld quality.

- Defect Detection and Sizing: AUT can detect and size various types of flaws, including cracks, lack of fusion, and lack of penetration, providing detailed information for integrity assessment.

- Data Recording and Analysis: AUT systems capture extensive inspection data, allowing for detailed analysis, reporting, and comparison over time.

- Improved Safety and Integrity: AUT helps identify and mitigate potential defects, enhancing the safety and long-term integrity of pipelines and cylindrical structures.

Limitations:

- Surface Preparation: Adequate surface preparation is critical to ensure optimal coupling between the ultrasonic probes and the weld surface, as poor coupling can impact the accuracy of the inspection results.

- Equipment Complexity and Cost: AUT systems require specialized equipment and trained operators, which can involve higher initial investment and operational costs.

- Limited Accessibility: AUT may face challenges in inspecting complex geometries or areas with restricted access, potentially necessitating supplementary inspection methods or techniques.

- Operator Training: Skilled operators are required to set up and interpret the inspection data accurately, highlighting the importance of proper training and qualification.

When conducting AUT of girth welds, compliance with applicable codes, standards, and guidelines is crucial. Regular maintenance, calibration, and validation of the AUT system are necessary to ensure accurate and reliable inspection results. Combining AUT with other inspection methods, such as visual examination or radiographic testing, can provide a more comprehensive assessment of weld integrity.

Copyright © 2024 Brotherhood Technical Services Company - All Rights Reserved.

Powered by BTECH

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.