MFL TANK FLOOR CORROSION MAPPING

Introduction

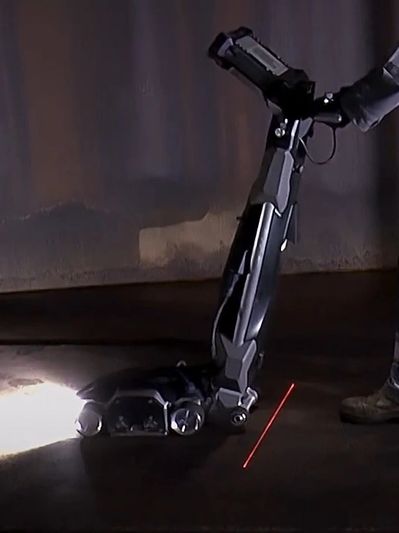

MFL tank inspection relies on the principle of magnetic flux leakage. The tank's floor, walls, and roof are magnetized using strong magnets, creating a magnetic field within the tank. Any defects or discontinuities in the tank's metal structure, such as corrosion, pitting, or cracks, cause localized leakage of the magnetic field. These leaks are detected by sensors (Hall effect sensors) placed on the tank's surface, allowing for accurate detection and evaluation of the defects.

Application:

MFL tank inspection is widely used in the petroleum industry to assess the condition of aboveground storage tanks. It helps identify corrosion, erosion, weld defects, and other structural issues that can compromise the tank's integrity. MFL inspection is particularly effective for double-bottom tanks and tanks with external corrosion protection.

Standard Code Reference:

Several standards and codes provide guidelines for MFL tank inspection, including

- API 653 (American Petroleum Institute) - "Tank Inspection, Repair, Alteration, and Reconstruction," and

- EEMUA 159 (Engineering Equipment and Materials Users Association) - "Above ground flat bottomed storage tanks: a guide to inspection, maintenance, and repair."

Advantages:

- High Sensitivity: MFL inspection can detect small defects and corrosion pits that may not be easily visible to the naked eye.

- Rapid Inspection: MFL scanners can cover large areas quickly, reducing inspection time.

- Non-Intrusive: The inspection is performed from the outside of the tank, eliminating the need for entry and minimizing downtime.

- Quantitative Data: MFL provides quantitative measurements of defect size and depth, aiding in accurate assessment and decision-making.

Limitations:

- Limited Accessibility: MFL inspection is not suitable for inaccessible areas, such as the tank's underside or areas obstructed by internal components.

- Surface Conditions: MFL requires a clean and dry surface for accurate inspection. Coatings, paint, or debris can interfere with the results.

- False Positives: MFL can occasionally produce false indications, requiring further examination to confirm defects.

- Calibration: MFL equipment needs regular calibration to ensure accurate measurements.

It's important to note that while MFL is a valuable inspection technique, it should be used in conjunction with other NDT methods to obtain a comprehensive assessment of tank integrity. Additionally, local regulations and industry practices should be followed when conducting tank inspections.

Copyright © 2024 Brotherhood Technical Services Company - All Rights Reserved.

Powered by BTECH

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.