PHASED ARRAY ULTRASONIC TESTING (PAUT)

Introduction

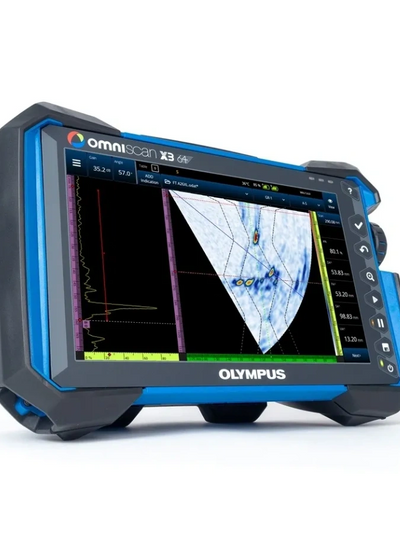

PAUT works on the principle of phased array technology, which involves using multiple ultrasonic transducers that can be individually controlled. By manipulating the timing and amplitude of the ultrasonic waves emitted by each transducer, a focused beam can be generated and steered electronically. This allows for precise scanning and imaging of the inspected material, enabling the detection of defects such as cracks, inclusions, and thickness variations.

PAUT with TFM and FMC combines the principles of phased array technology, total focusing method, and full matrix capture. TFM utilizes advanced algorithms to focus the ultrasonic beam in real-time at multiple points within the inspection volume, providing enhanced resolution and imaging capabilities. FMC involves acquiring the complete matrix of data by pulsing each element of the phased array transducer sequentially. This data matrix allows for extensive post-processing and advanced imaging techniques.

Application:

PAUT is widely used across various industries for inspecting welds, forgings, castings, and other critical components. It is particularly effective for detecting and characterizing discontinuities in complex geometries and materials, including corrosion, delaminations, and weld defects. PAUT is commonly employed in industries such as oil and gas, aerospace, power generation, and manufacturing.

PAUT with TFM and FMC is particularly suitable for the detection and characterization of HIC, a type of cracking caused by the presence of hydrogen in the material. It is commonly used in industries such as oil and gas, petrochemicals, and power generation, where hydrogen-related damage can occur in equipment, pipelines, and vessels. This technique helps identify the extent, location, and severity of HIC, aiding in maintenance and repair decisions.

Standard Code Reference:

Several international standards provide guidelines for PAUT, including

- ASME Section V, Article 4 - "Ultrasonic Examination";

- ISO 13588 - "Non-destructive testing - Ultrasonic testing - General principles"; and

- ASTM E2491 - "Standard Guide for Evaluating Performance Characteristics of Phased-Array Ultrasonic Testing Instruments and Systems."

- API 579-1/ASME FFS-1 (Fitness-for-Service),

- API 5L (Specification for Line Pipe), and other industry-specific guidelines. These standards provide guidance on inspection methodologies, acceptance criteria, and assessment procedures for detecting and evaluating HIC and other forms of damage.

Advantages:

- High Precision: PAUT offers precise imaging and sizing of defects, providing detailed information about their size, location, and orientation.

- Versatility: The technique can be adapted to various inspection scenarios, including complex geometries, curved surfaces, and thick materials.

- Faster Inspection: PAUT allows for rapid scanning and data acquisition, reducing inspection time compared to conventional ultrasonic testing.

- Real-time Imaging: PAUT provides real-time B-scan and C-scan imaging, enabling immediate visualization and analysis of the inspected area.

- Data Recording and Analysis: PAUT systems can store inspection data for future reference and analysis, facilitating documentation and reporting.

- Enhanced Resolution: TFM and FMC techniques provide high-resolution imaging, enabling detailed detection and characterization of HIC and other defects.

- Improved Sizing Accuracy: The algorithms used in TFM allow for accurate sizing and depth determination of HIC flaws, aiding in integrity assessment.

- Flexible Inspection Setup: PAUT with TFM and FMC allows for adjustable focal points and beam steering, enabling comprehensive coverage of complex geometries.

- Detailed Data Acquisition: FMC captures the complete data matrix, enabling advanced post-processing, analysis, and reevaluation of inspection data.

- Time Efficiency: PAUT with TFM and FMC can provide faster inspections compared to conventional techniques, reducing downtime and costs.

Limitations:

- Operator Skill: Proper training and experience are required to set up and interpret the data obtained from PAUT with TFM and FMC accurately.

- Equipment Cost: Phased array ultrasonic equipment can be more expensive compared to traditional ultrasonic testing systems, making initial investment higher.

- Equipment Complexity: The implementation of TFM and FMC requires specialized software and advanced hardware, which may increase the complexity and cost of the inspection setup.

- Data Processing Time: The extensive data captured during FMC inspections may require additional time for post-processing and analysis

- Surface Conditions: Surface roughness, coatings, and other factors can affect the accuracy and quality of the ultrasonic signals, potentially impacting the detection of HIC and other defects.

- Limited Penetration: The depth of inspection for PAUT is dependent on the material properties and frequency used, which may limit its applicability in some cases.

- Calibration and Standardization: Proper calibration and verification of PAUT equipment are essential to ensure accurate and reliable results.

It's important to note that PAUT with TFM and FMC for HIC inspection should be conducted in accordance with relevant industry standards, guidelines, and best practices. The specific inspection requirements and conditions of the equipment being examined should be taken into account when implementing this technique.

Copyright © 2024 Brotherhood Technical Services Company - All Rights Reserved.

Powered by BTECH

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.